Features

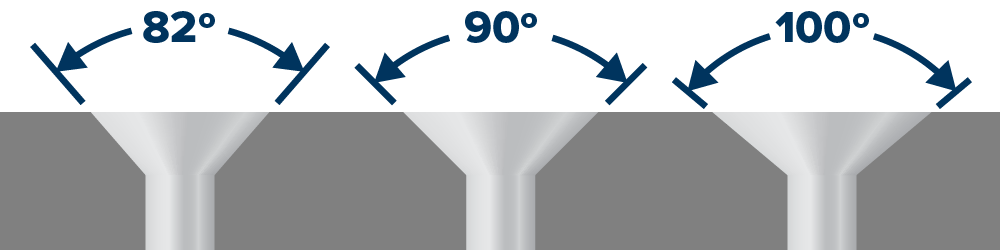

Countersinks

Add 82°, 90°, or 100° countersinks in your panel. The dimensions we need to know are inner diameter, outer diameter, degree, XY locations, and the front/back designation. We will be in touch shortly after your order is placed to confirm these details.

Adding countersinks increases the lead-time by 1 business day.

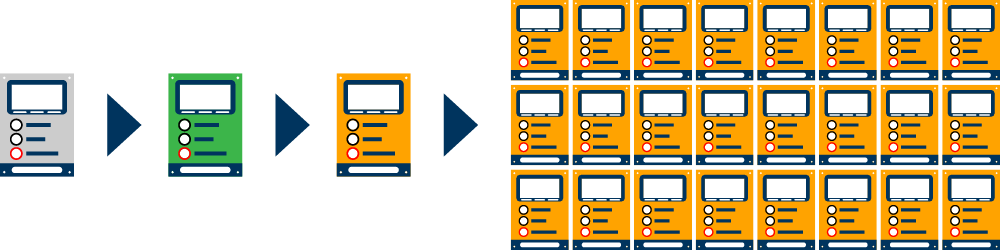

Prototyping Efficiency

Avoid double tooling charges and benefit from the lower costs of a full run production company by running your prototype through Front Panel Creator and then transitioning your final design to our sister company, Precision Graphics, for your full production runs. Click here for more details.

Dimensions & Tolerances

Our pricing tool can resize your DXF or STP cut file following Imperial and Metric standards. We process parts up to 46″ x 22″. Each part will be held to a +/- 0.005″ tolerance.

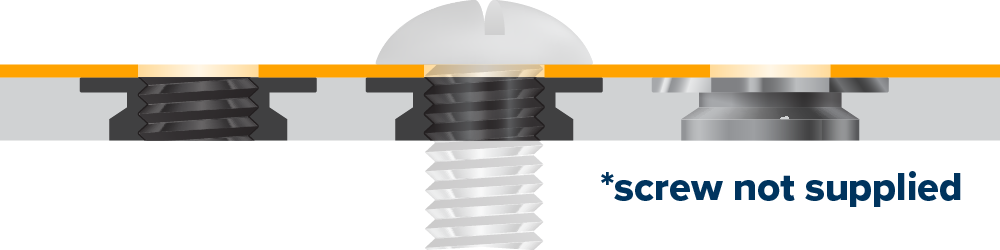

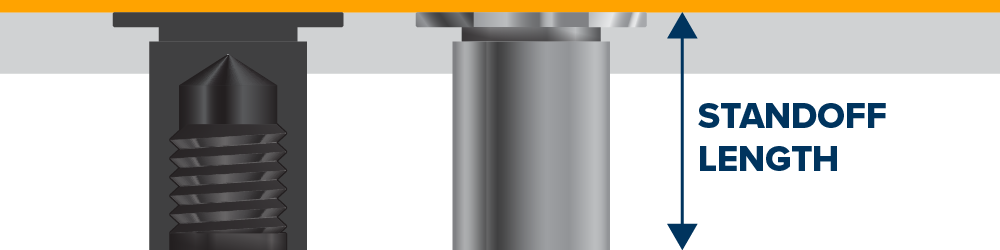

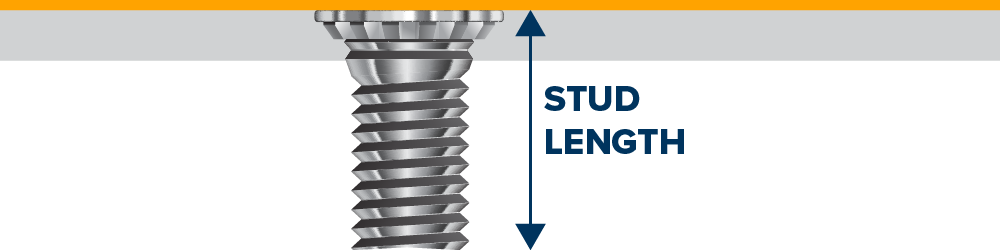

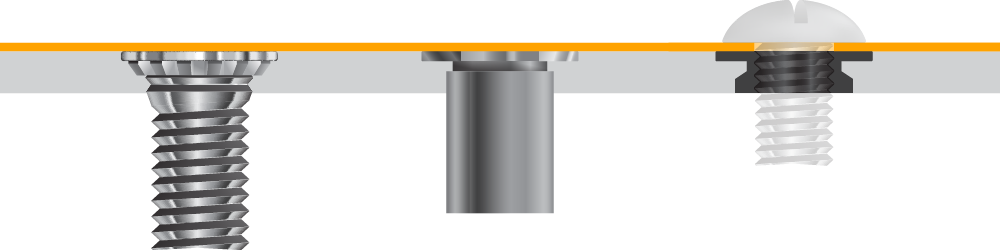

Studs, Standoffs, and Fasteners

Front Panel Creator offers flush-head studs, blind standoffs, and flush clinch fasteners as hardware that can be inserted into your aluminum sub-panel. All hardware is stainless steel for strength and corrosion resistance. All hardware is also press-fit in thru-holes to guarantee the strongest torque rating. We do not use glue to secure hardware because each piece is secured mechanically in the sub-panel. We will be in touch shortly after your order is placed to confirm the details of the hardware you need.

Adding hardware increases the lead-time by 1 business day.

Flush Head Studs

Blind Standoffs

Flush Clinch Fasteners

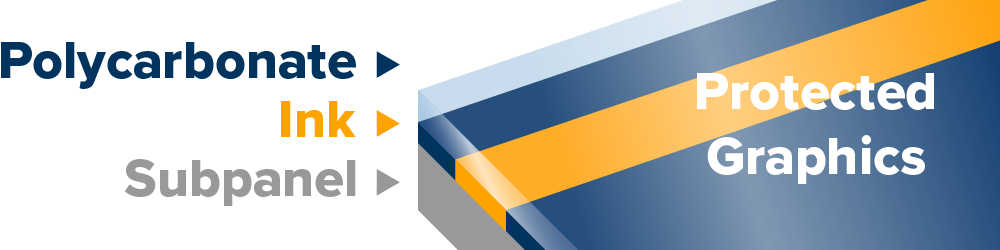

Subsurface Printing

Subsurface printing is when the ink is applied to the second surface (the back) of a material. This protects the ink from abrasion, chemicals, and everyday use. It allows the surface of the overlay to be cleaned easily without damaging the graphics underneath. For demanding outdoor graphic applications we offer a fine matte weatherable HP12W with chemical and UV resistance.

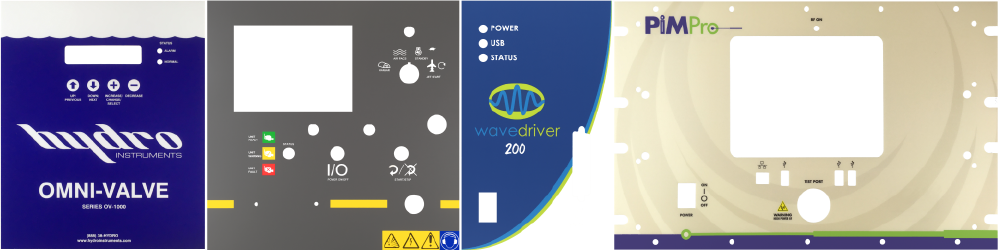

Graphic Overlays

Your graphic overlay will be printed sub-surface on clear 0.010″ thick Lexan (polycarbonate). Overlays are digitally printed with incredible quality and resolution. A selection of top surface finishes are available which include velvet gloss, velvet matte, and a fine matte HP12W which is weatherable. After printing, overlays are bonded to their sub-panels using 3M MP467 Adhesive.

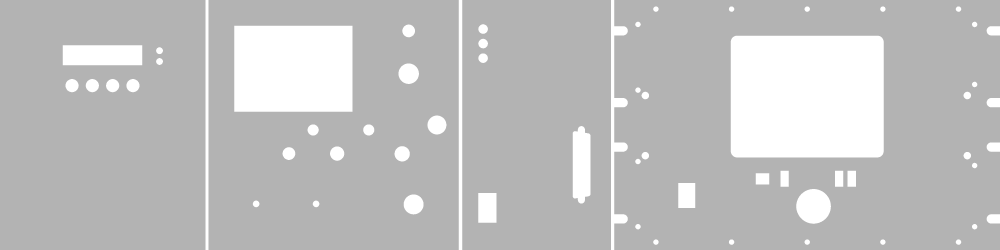

Subpanels

Your sub-panel will be manufactured of 5052 Aluminum, chosen for its durability, strength, and corrosion resistance. Select from the following gauges: 0.040″, 0.050″, 0.063″, 0.080″, 0.090″, 0.100″, and 0.125″

Complete Panel Manufacturing

Front Panel Creator exists to make complete panel manufacturing simple and fast. We use your DXF or STP cut file to manufacture both the rigid sub-panel and graphic overlay. Both layers of your panel will have excellent registration because they are both manufactured in-house here at Front Panel Creator.

Use your own software

In addition to excellence, we value efficiency. Learning a new software for a single aspect of your product is not efficient. Avoid doubling your work load and use the software you already own to export a simple DXF or STP cut file for our pricing tool.

Instant Pricing

Our pricing tool provides a real-time purchase price for your part. You can see live updates to prices based on material selection, add-on hardware, countersinks, and quantity…then order your parts immediately!

Standard 3-Day Lead Time

No need to pay extra for faster lead time! Our shop is set up to process jobs of reasonable quantities in 3 business days. For larger quantities we will contact you to arrange partial delivery within the standard lead time. Lead time begins when we receive approval on the proofs for your job.

If your part includes hardware or countersinks we add 1 additional day to the lead time for each process.