Sheet metal fabrication is an essential process in creating front panels for a wide variety of industries like aerospace, audio, marine, and electronics. Operators interact constantly with front panels, pushing buttons, turning knobs, touching screens, and processing the information it displays. At the very least, it should be durable and functional. Fabricating a front panel with sheet metal is one of the best ways to make sure it is.

What benefits do you gain by using sheet metal for your front panel designs? Do we recommend any materials? Want to know more about the technologies we have available to achieve your specific design?

Benefits

Its primary benefits are strength and durability. Other materials, like acrylic and other plastics, may not hold up over time or in certain environments.

While front panels can be manufactured with other materials, sheet metal is the most common and has some benefits.

Sheet metal also allows features to have great precision, dimensional stability, and complexity.

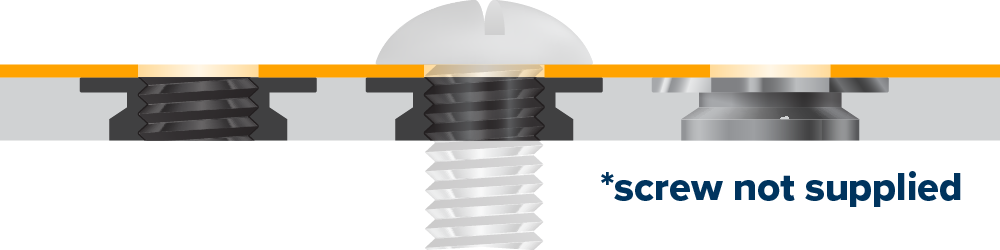

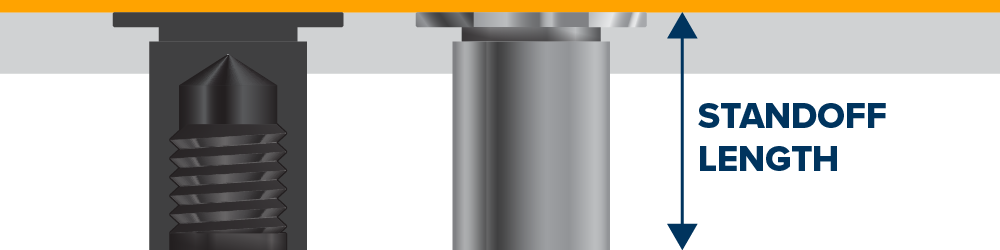

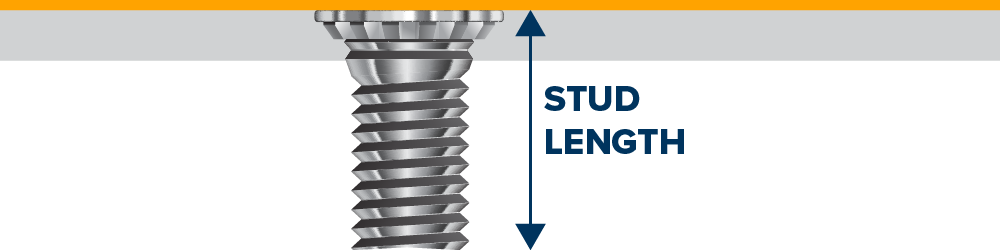

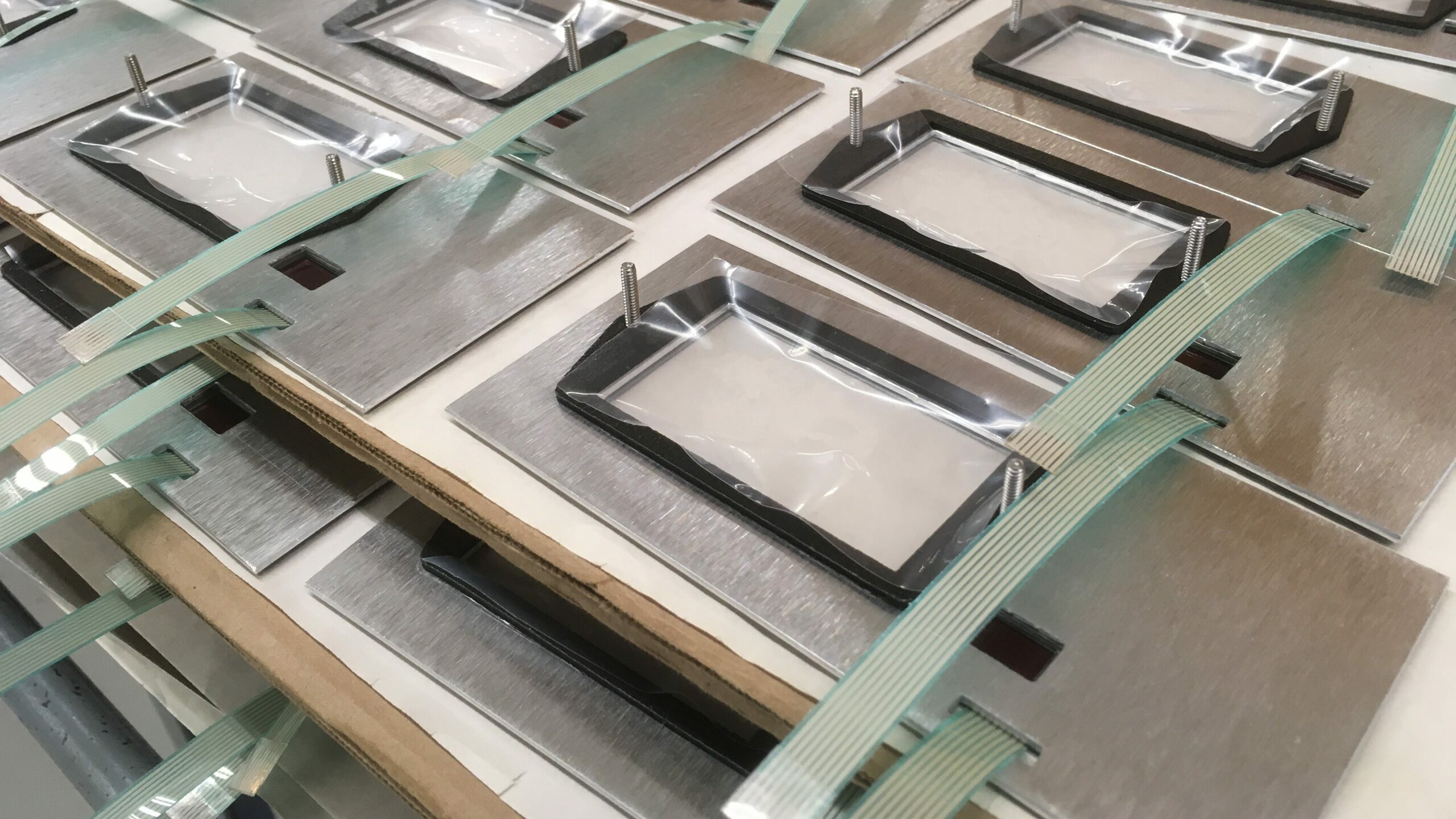

Aluminum and steel also accept hardware inserts, adding capabilities like PCBs, displays, and direct integration with the main unit.

Fabrication Technologies

Precision Graphics employs multiple sheet metal cutting technologies to achieve the features of our customer’s designs. Our range of capabilities give us flexibility when quoting and ensures efficient manufacturing and competitive pricing.

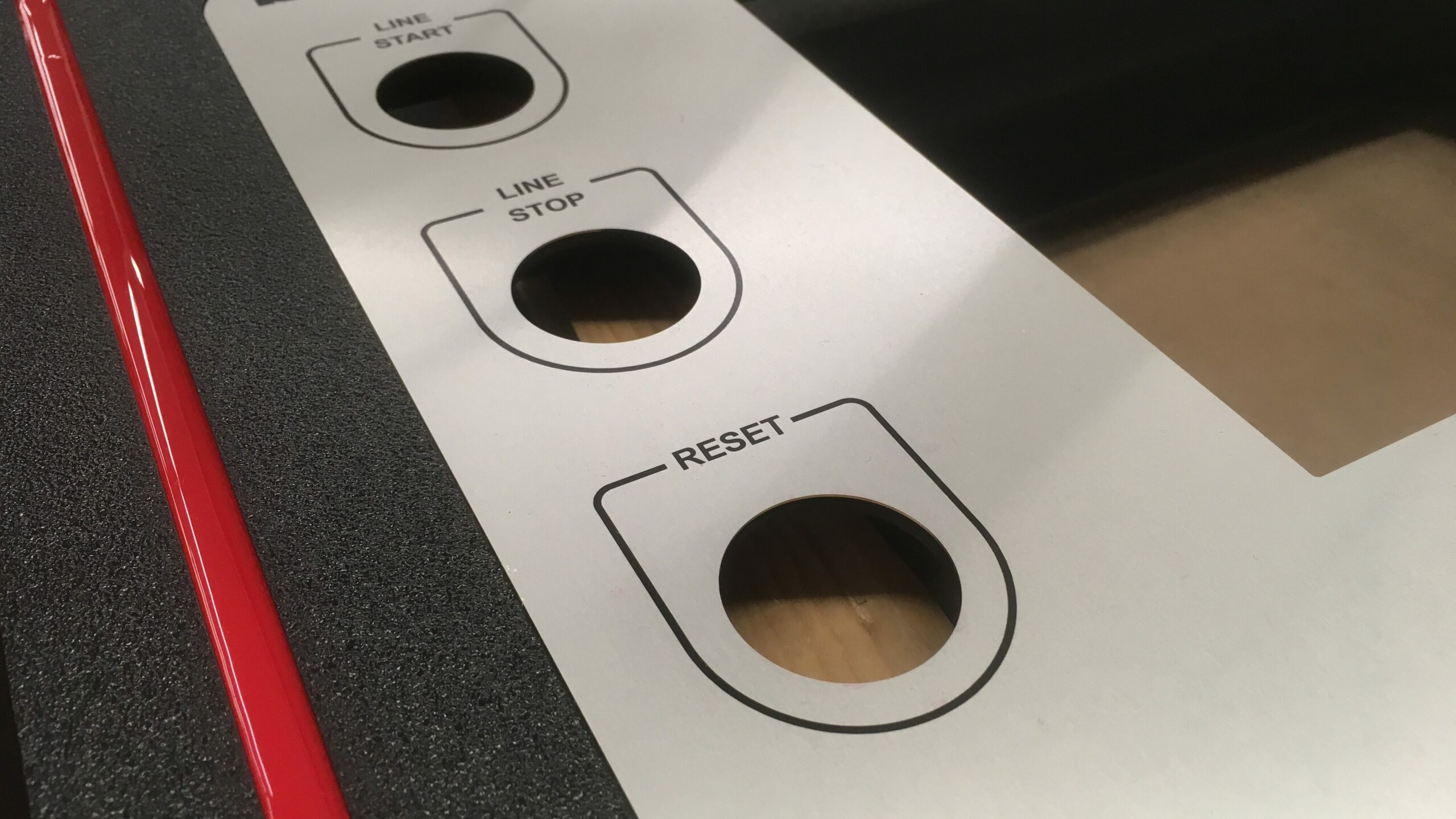

Laser cutting is a precise method that produces intricate designs on two-dimensional panels. Our nitrogen gas fiber laser delivers clean edges that reduce the effort needed for deburring.

CNC milling is also precise, but adds the ability to create 3-dimensional features like countersinks, counterbores, pockets, chamfers, and more. The edge quality of a milled panel is second to none.

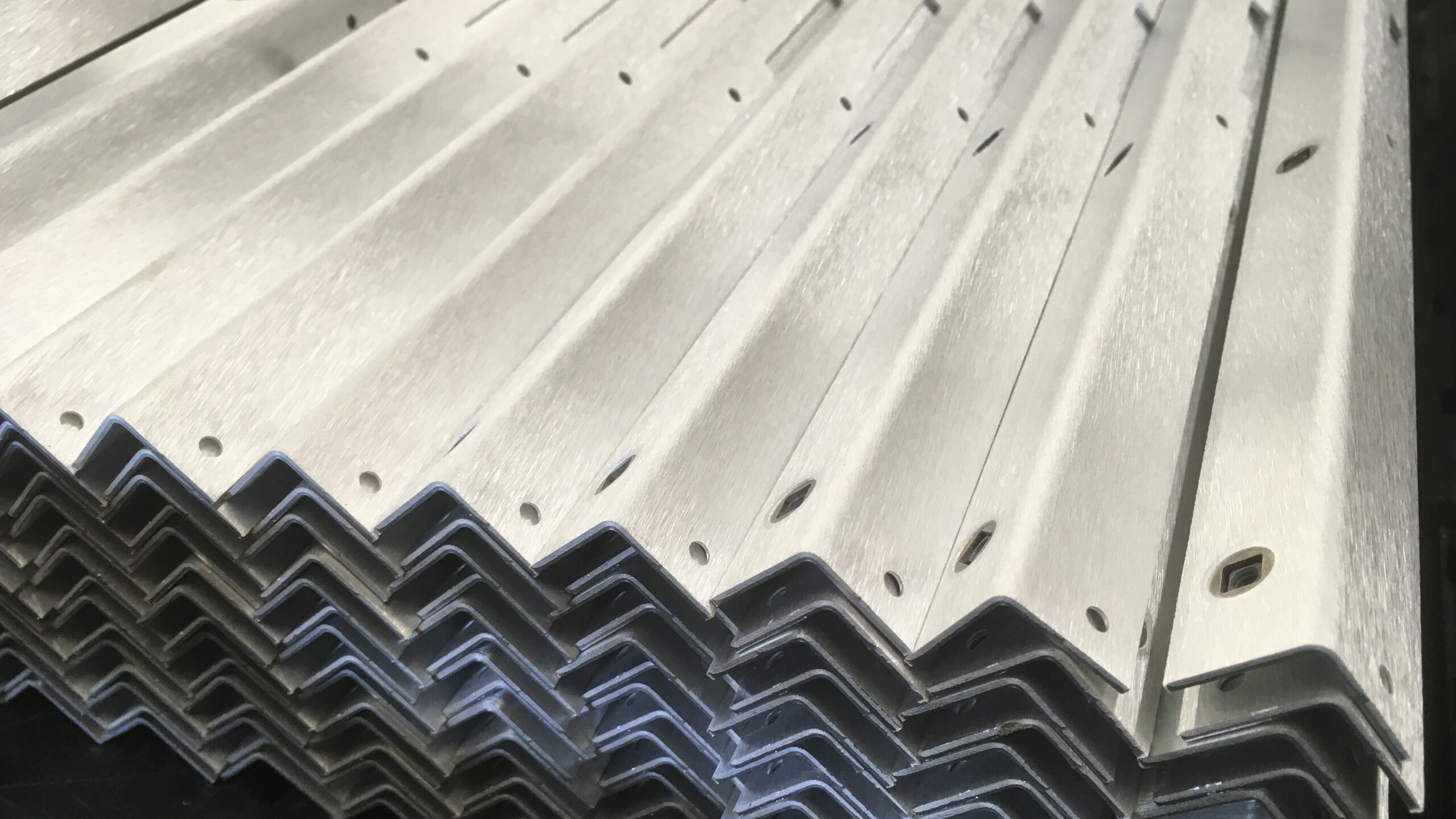

CNC punching is a fast and cost-effective method that is ideal for creating simple shapes and excels at large quantities.

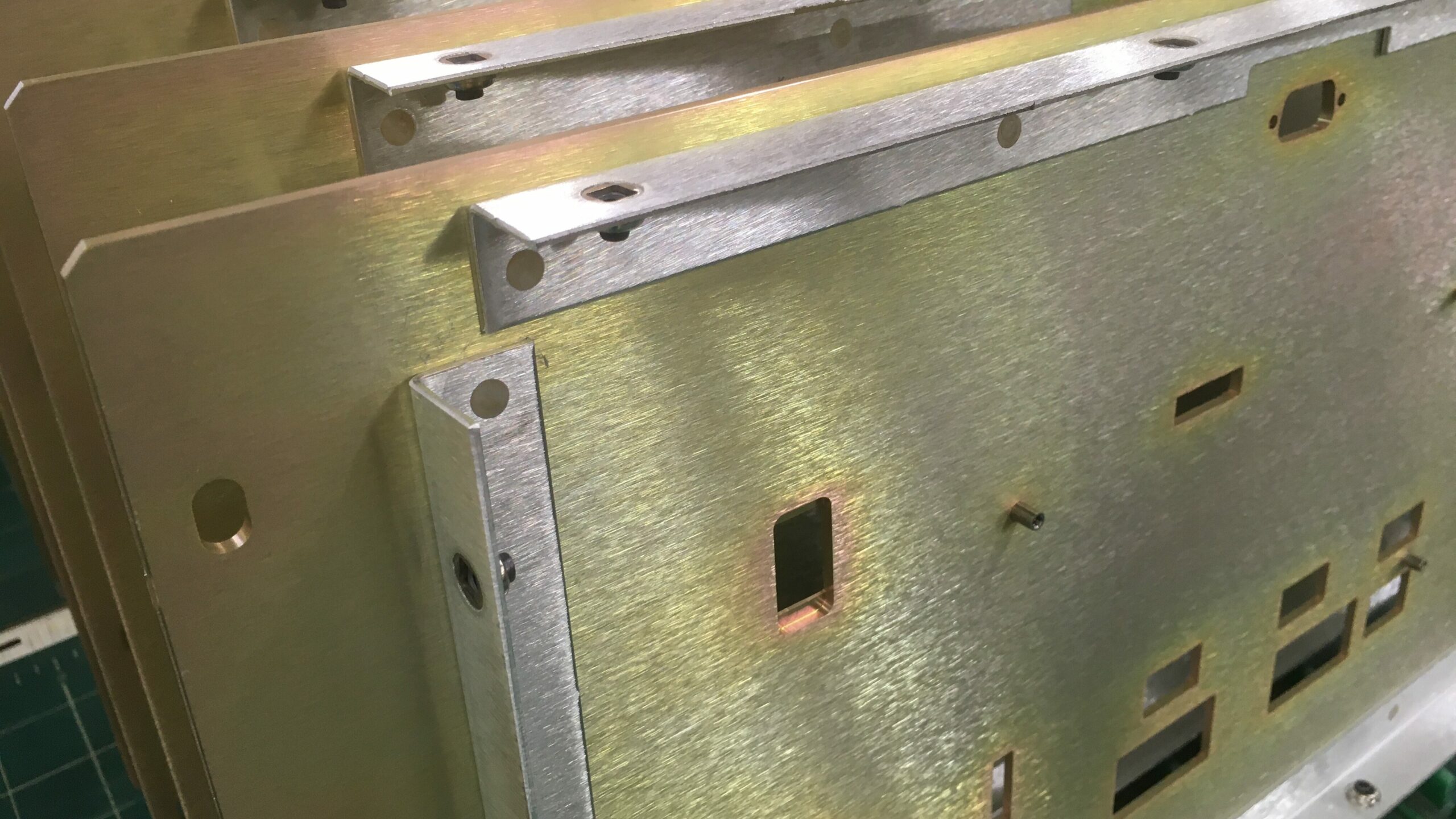

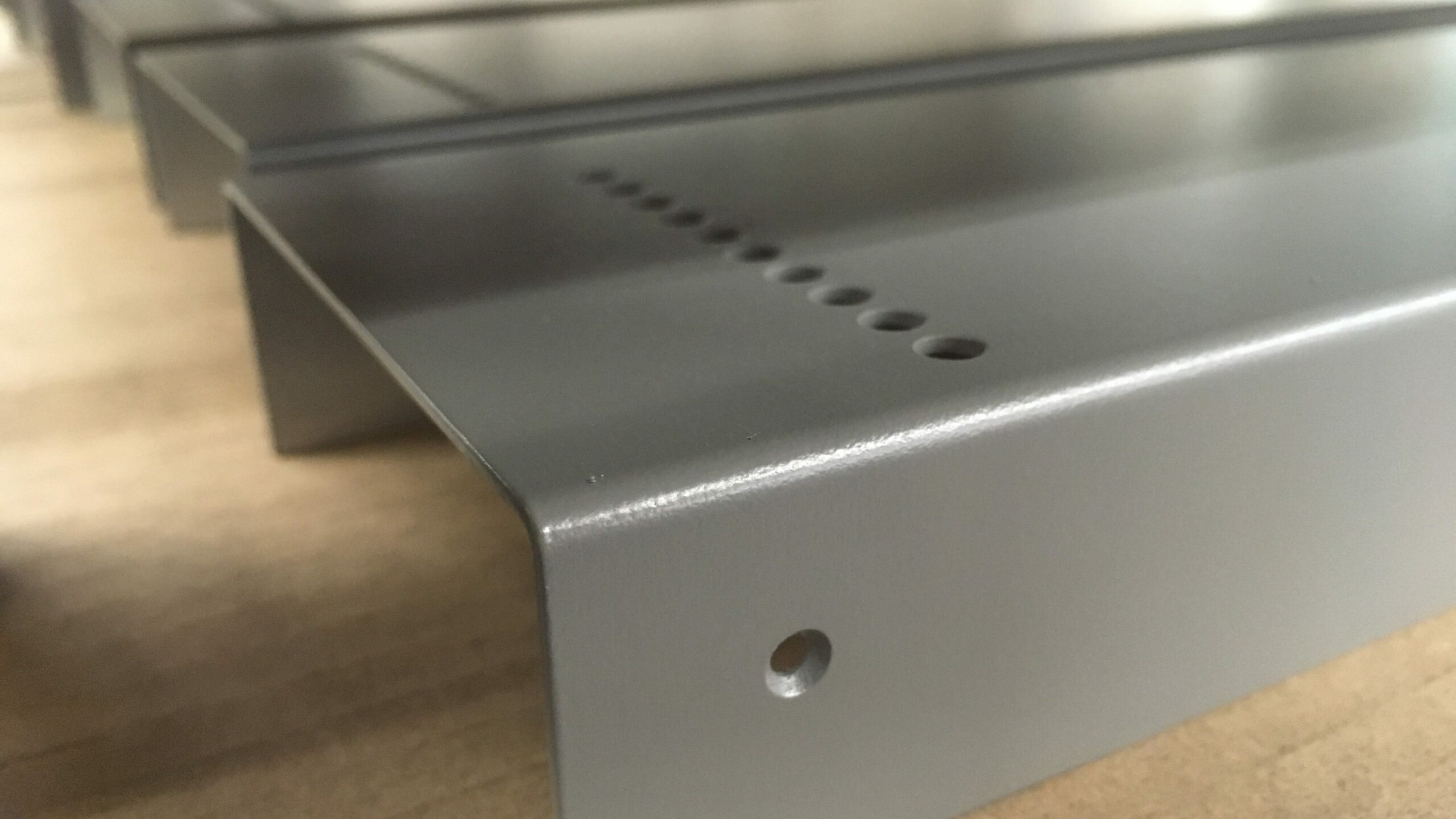

Some of our customers’ panels include brackets or flanges in their design. This can be for added rigidity or to accommodate a more complex integration with its main unit. We rely on our electric brake press to precisely bend these parts.

Materials

The most common materials chosen for front panels is aluminum and steel, both cold-rolled and stainless. Each material offers its own set of properties and advantages. Choose a material that makes the most sense for the needs of your front panel.

Aluminum is available in our standard 5052-H32 for its corrosion resistance and strength. Panels with three-dimensional features like pockets and counterbores should be manufactured with aluminum, as many shops do not mill steel. Finished panels can be kept with their milled finish, powder-coated, painted, anodized, or clear or color chromated.

We also offer 6061-T6 aluminum, but its use is not common or needed in most cases.

Steel is a good choice for increased strength when weight is not an issue or for cost-cutting measures. Nameplates are a common application for stainless steel.

Industries

The aerospace industry heavily relies on sheet metal fabrication for creating its panels. Front panels in airplanes, spacecraft, and their supporting ground equipment need to be lightweight, durable, and able to withstand extreme conditions. Sheet metal allows manufacturers to create user interface panels that meet these requirements.

The audio industry is another sector that relies heavily on sheet metal machining for creating high-quality front panels. Few industries are as focused on the visual appeal of their front panels! Some of the best looking panels are done for companies in the audio industry, many of them showcasing the beauty of MetalPhoto®. Machining allows manufacturers to create complex shapes and designs that enhance the aesthetic appeal of the equipment.

Other industries that can benefit from these features are electronics, automotive, and marine to name a few. The need for front panels is plentiful because they are necessary interfaces between a machine and its operator.

By choosing the right sheet metal fabrication technology and material, you can create front panels that are visually appealing, durable, and functional!