Graphic Overlays

Quote Request

They look perfect because they are

Precision Graphics takes great pride in the print quality of our graphic overlays. Each overlay is printed with care and precision, giving attention to each detail including colors, dimensions, and features. After printing, each overlay is aligned perfectly with all of the other relative components to ensure that the completed part is as beautiful as it is functional.

Perhaps you already have your rigid layer taken care of. We are happy to provide your overlay service for your panel separate from a rigid layer. Just send us your schematics and we will match right up to it!

Graphic Overlay Customizations

Graphic overlays and labels can be digitally printed as well as screen printed. Most of our high resolution graphics are printed on the second surface, which is the back side of polyesters, polycarbonates, as well as acrylic. This subsurface printing protects the ink behind the plastic it is printed on. It is most effective against abrasion, aggressive chemicals, and of course, every day handling. The overlay can be further protected by placing it inside a recessed pocket milled from the metal sub-panel. This shields the edge of the overlay by making it flush with the surface of the sub-panel.

Materials & Finishes

Standard finishes for polyester and polycarbonate include anti-glare (low gloss), gloss, brushed and velvet, with velvet being the most popular to hide fingerprints. Choose from a variety of gauges and finishes both in polyester and polycarbonate. Some polycarbonate finishes include velvet gloss 8A35, velvet matte 8B35, and fine matte HP12W in addition to many others. Some polyester finishes include gloss, 55% gloss, and fine texture. With selective texturing, designated areas of an overlay can be with gloss or diffused. Selective texturing is most common with windows.

Digital Printing

Digital printing is becoming more popular for creating graphics, and for good reasons. Our digital printers have a large format to accommodate oversized graphics. A resolution up to 1,200 DPI provides fine details and superior gradients. Graphics can be printed directly from your electronic file. Minimal tooling and set up means it is perfect for prototypes and short runs.

Screen Printing

Screen printing is the most popular method of printing. We computer-match our UV curable inks to guarantee an exact color reproduction. These inks are used with high tension polyester screens to print features as small as .005” across. This is a scale suitable for halftones. Our screening process is also suitable for the ever important circuitry, and parts that require selective texturing, which creates the illusion of separate window lenses with a flush, sealed construction.

Color Matching

The Pantone, RAL, and L*a*b* color matching systems are familiar tools here. The graphic designers color match with the latest vector based software. The screen printing department color matches with the exact science of UV curable ink mixing formulas. The painting department color matches with computer databased paint formulas that utilize a mix of 16 base colors. No matter the media, we make sure the beauty of your panel looks the way it should.

Adhesives

Choose from a variety of adhesives to affix your overlay to its panel. We use only the highest quality adhesives from the 3M brand to ensure permanence. Depending on your panel’s final application, you can choose the industry standard 3M 467 or 468, or if your panel requires adhesive with low surface energy you can choose 3M 300LSE. Does your panel or overlay require a more specialized adhesive? Let us know!

Pockets

Precision Graphics understands that your panel sometimes has variable information. For this dynamic, we build a pocket into your panel with a front, side, or rear entrance to slide in a label. Your slide label remains protected behind a clear window in the graphic layer film.

Shapes & Sizes

We can produce graphic overlays and panels up to 48” x 96”. Depending on the design and features desired, a screen print, digital print, or hybrid of the two may be required for cost efficiency or to meet your specifications.

Interior Cutouts

Every material we print on follows seamlessly through our diverse array of automated cutting machines. By delegating the perfect machine for each part, we can minimize set up and lead time, which in turn reduces cost. Regardless of which machine or material is used, your parts will always be precisely cut.

Windows

We offer windows on the graphic layer with different finishes. Selective texturing creates the illusion of separate window lenses with a flush, sealed construction. Glossy, semi-gloss, frosted, antiglare, dead-front and translucent windows are all available options. Furthermore, windows can be colored and tinted with different transparent and translucent inks.

Embossing

We have many customers who design emboss into their panels. It is a great option for making important features more prominent or providing tactile feedback. The most common is pillow embossing for buttons and LED’s. Rim embossing and braille are also common, but there are many options to choose from.

Need a complete solution?

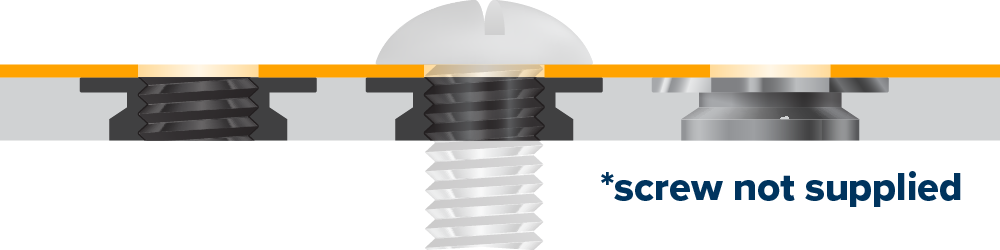

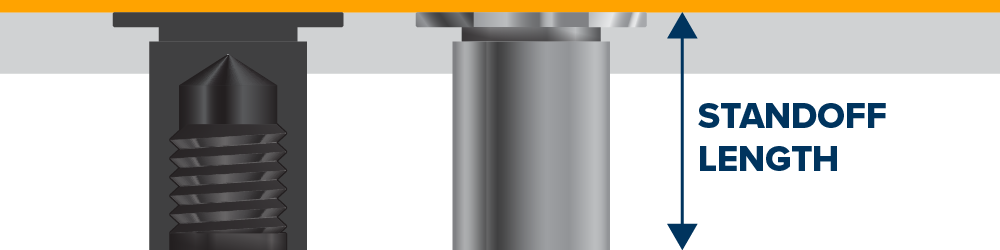

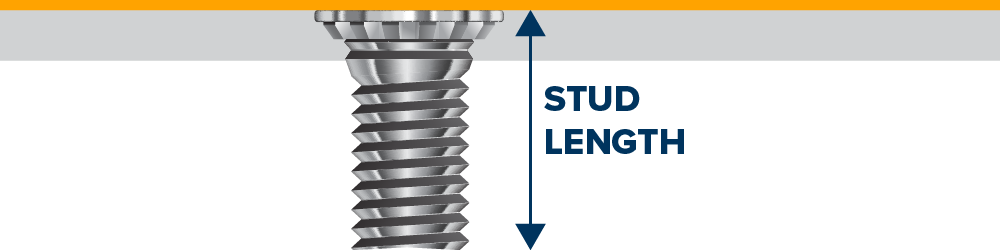

Assembly

On-site assembly ensures the overlay, circuitry, and sub panel layers align properly. The strongest bond between these layers is normally accomplished by using a pressure sensitive acrylic adhesive (PSA) in combination with a high pressure flat bed roller application. Here is where all the layers join and edge-flush construction is realized. The assembly department works closely with the others by its very nature, so if there are concerns for how a panel assembles, our team will make sure they are resolved.